Smarter processes, stronger efficiency, and better growth for modern manufacturers

⚙️ The Manufacturing Balancing Act

If you’ve worked in manufacturing, you already know the juggling act:

📦 Managing production schedules

🛠️ Tracking raw materials and suppliers

⏱️ Meeting customer deadlines

🧾 Staying compliant with safety and quality standards

💰 Keeping costs under control

One small delay in raw materials or a missed quality check — and suddenly the whole production line feels the ripple.

That’s why manufacturers worldwide are turning to ERP (Enterprise Resource Planning) systems — and even more importantly, custom ERP solutions designed around their unique workflows.

🤔 What is ERP, Really?

Think of ERP as the central nervous system of your business.

It connects every department — from purchasing to production to finance — so everyone works with the same data, in real time.

For manufacturers, ERP means:

✔️ Knowing stock levels instantly

✔️ Smarter demand forecasting

✔️ Automated production schedules

✔️ Supplier management with less admin

✔️ Live cost tracking

✔️ Stress-free compliance reporting

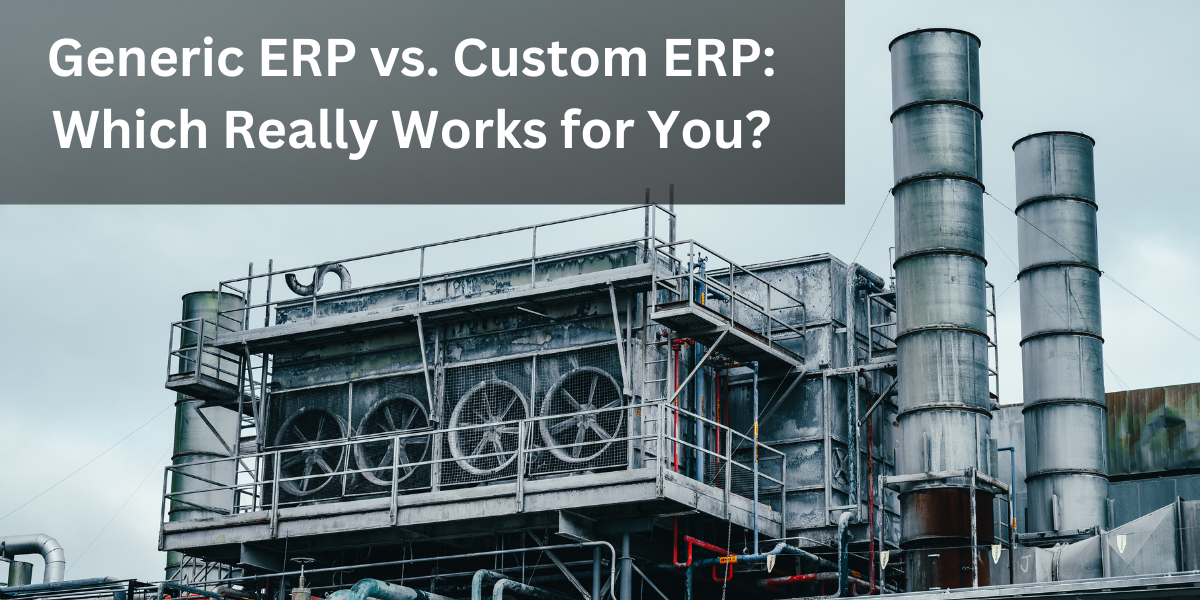

🎯 Why “Custom” ERP Matters in Manufacturing

Here’s the truth: off-the-shelf ERP often doesn’t fit.

Every factory floor runs differently. Machines, workflows, supply chains, and compliance requirements all vary. A generic ERP forces you to adapt to the software.

A custom ERP flips that around — it adapts to you.

That’s where the revolution begins.

🚀 How Custom ERP is Transforming Manufacturing

1️⃣ Smarter Inventory & Supply Chain

No more overstocking or running out of raw materials. Reorder alerts, real-time tracking, and supplier integration keep production flowing smoothly.

2️⃣ Real-Time Production Monitoring

Managers see machine performance, downtime, and output instantly. No more waiting for end-of-day reports.

3️⃣ Built-In Quality Control

Custom workflows mean your inspections happen at exactly the right stage — with instant alerts if something goes wrong.

4️⃣ Financial Oversight That Actually Helps

Track material costs, labour, and profitability in real time. No surprises at the end of the month.

5️⃣ Compliance Without the Headache

Safety checks, audit logs, and automated reporting built into your system mean less time on paperwork.

6️⃣ Collaboration Across the Business

From shop floor operators to directors, everyone sees the same data. No silos. No crossed wires.

📖 Real Story: A Midlands Manufacturer

One of our clients relied on spreadsheets and email trails for years. It worked — until it didn’t. Orders got lost, inventory wasn’t accurate, and reporting for investors took weeks.

We built a custom ERP for them. Within 12 months:

📈 Production efficiency rose by 30%

♻️ Inventory waste dropped dramatically

🗂️ Reporting time shrank from 10 days to 2

😊 Customers saw faster turnaround times

This wasn’t “just software” — it reshaped how their business operated.

🔮 The Future of Manufacturing

With Industry 4.0, IoT, and predictive analytics reshaping factories, ERP is the backbone that ties everything together.

A custom ERP means you’re not just tracking issues — you’re predicting and preventing them. You’re not just counting costs — you’re optimising them. You’re not just making products — you’re building resilience.

✅ Final Thoughts

Manufacturing is about precision, efficiency, and constant improvement. Today, that requires more than skilled workers and quality machines. It requires the right digital backbone.

A custom ERP solution gives manufacturers the clarity, control, and confidence they need to thrive in a global, competitive, digital-first industry.

FAQs

Q. Why should a manufacturer choose a custom ERP over an off-the-shelf system?

Q. Isn’t a custom ERP more expensive to set up?

Q. How long does it take to implement a custom ERP system?

Q. What kind of improvements can we expect after switching to a custom ERP?

Q. Is custom ERP scalable if my business grows?

Related Blogs

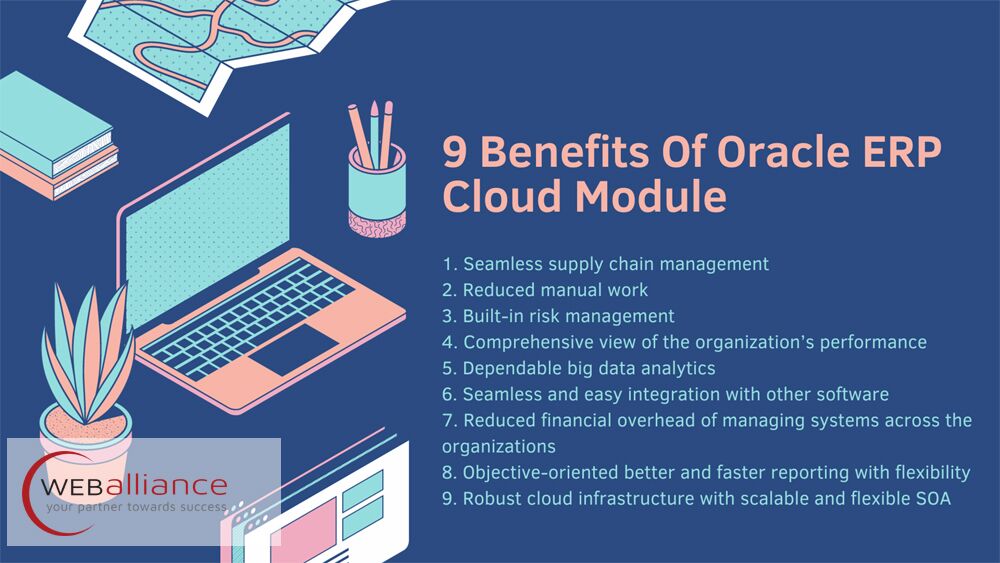

Top 9 Oracle ERP Modules You Should Ask a Custom ERP Software Developer

Enterprise resource planning (ERP) modules have become a …

How to Improve ERP Benefits with AI Integration to Transform Your Business

A custom-to-need ERP (Enterprise Resource Planning) …

ERP Software for Textile Industry: Its Need and Its Benefits

The textile sector is at the forefront of rapid growth and …